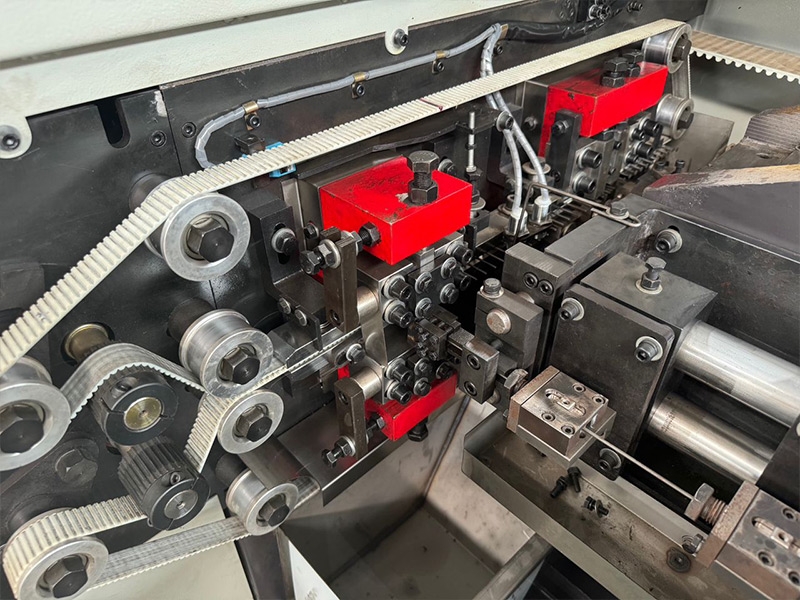

KM-700 High-Speed Nail Making Machine ensures maximum efficiency in nail production with a production capacity of up to 850 nails per minute. Operating within a range of 2.5–4 mm wire diameter and 50–100 mm nail length, this powerful system offers a failure rate below 0.1% and sensor-assisted automatic control for flawless production.

Thanks to its easy operation and maintenance features, a single operator can run five machines simultaneously; no skilled labor is required. The machine provides high accuracy in production through sensors that detect nails of different lengths.

It offers 50–55% savings in labor costs during nail production and operates without the need for a high-pressure air pump. The active wire feeding system ensures straight shafts and consistent lengths regardless of the coil weight.

The spare parts are durable and economical. Each new die and punch can produce at least 50 tons of nails before replacement, while each new blade can be re-sharpened and reused even after producing 20 tons of nails. This provides long-term efficient use with minimal maintenance costs.

The service life of the machine exceeds 10 years. Equipped with 7 alarm sensors, it protects the machine and guarantees high nail quality. With its 5.5 kW motor power and 2700 kg solid body, it maintains high performance and stability for many years.

|

Wire Diameter |

2.5-4 mm |

|

Nail Length |

50-100 mm |

|

Capacity |

650 -850 pcs/min |

|

Machine Motor Power |

5.5kw/h |

|

Weight |

2700 kg |

|

Main Machine Dimensions |

1350×1050×1100mm |

|

Control Cabinet Dimensions |

400x600x800mm |

|

Wire Reel Dimensions |

1500x800x350mm |